Structural Behavior of Freestanding Satin-Stitched Lace

An Experimental Evaluation in Embrilliance StitchArtist

Steve Medwin — Medwin Fiber Art

Introduction

Freestanding satin-stitched lace represents one of the most demanding use cases for machine embroidery. Unlike satin stitches placed on fabric, freestanding satin stitches must carry their own structural load once the stabilizer is removed. Curved geometry amplifies this challenge: stitch bundles compress on inner radii, spread on outer radii, and reveal weaknesses in underlay strategy long before purely aesthetic issues become visible.

This study set out to identify which parameters in Embrilliance StitchArtist actually determine structural stability in freestanding satin lace, and which parameters primarily influence appearance and tolerance. In particular, it examines the role of Freestanding underlay, its interaction with traditional underlay types, and the relative importance of underlay density versus satin stitch settings.

Materials, Equipment, and Context

All experiments were conducted on a Brother VE2200 embroidery machine using Madeira Polyneon 40 polyester thread for both top and bobbin threads. The lace was stitched on two layers of Vilene water-soluble stabilizer and digitized using StitchArtist version 1.190.

This configuration reflects a production-grade environment rather than a hobby setup. Machine variability was minimal, allowing observed behavior to be attributed primarily to digitizing choices rather than equipment limitations.

Geometry of the Test Sample

The test design measured approximately 25 × 55 mm and consisted of straight satin segments connected by curved elements of varying diameters (see Appendix A). Four curves were selected to span a wide range of curvature severity. The gentlest curve measured approximately 25 mm in diameter, while the tightest curve measured approximately 5 mm in diameter. Two intermediate curves, approximately 15 mm and 20 mm in diameter, completed the set.

The smallest curve, at roughly 5 mm, functioned as a near worst-case stress test. Any configuration that failed on this curve could not be considered robust, while configurations that survived this geometry reliably performed well on all larger curves.

Terminology and Parameter Separation

A strict separation between topstitch and underlay parameters was essential throughout this work.

Topstitch properties define the visible satin stitch and include Topstitch Width and Topstitch Density. Underlay properties define the structural support beneath the satin stitch and include four selectable underlay types—Edge Run, Parallel, Zigzag, and Freestanding—as well as adjustable parameters such as Underlay Length, Underlay Inset, and Underlay Density.

A key clarification emerged early: Underlay Length, Inset, and Density apply only to Edge Run, Parallel, and Zigzag underlay. These parameters do not affect the Freestanding underlay mesh itself. This distinction is critical, as misunderstanding it leads directly to misinterpretation of both documentation and results.

Experimental Approach

The investigation proceeded in stages. Five designed experiments were run which generated 75 test samples (see Appendix B).

Initial tests verified baseline behavior and confirmed that Topstitch Density could be held constant without compromising structural outcomes. All subsequent experiments fixed Topstitch Density at 4 so that structural changes could be attributed to underlay configuration, underlay density, or satin width.

The first major phase examined underlay configuration. Edge Run, Parallel, Zigzag, and Freestanding underlay were tested individually and in various combinations. Despite documentation suggesting that Freestanding underlay may be used alone, experiments consistently showed that Freestanding underlay by itself was insufficient to support curved satin stitches. Satin bundles separated on inner curves, edge cohesion suffered, and defects appeared even at moderate curvature.

In contrast, configurations combining Edge Run, Parallel, Zigzag, and Freestanding underlay produced stable, repeatable results. This finding became foundational and informed all subsequent testing.

With underlay configuration established, the next phase focused on Underlay Density. Multiple density values were evaluated while keeping underlay types constant. Across satin widths from 1.0 to 5.0 mm, an Underlay Density value of approximately 14 consistently provided the best balance between curve cohesion, edge stability, and tolerance to geometric variation. Denser underlay (lower density numbers) improved performance on the tightest curves, while looser underlay (higher density numbers) proved more forgiving for wider satin stitches.

The final phase combined satin stitch width and underlay density in a structured design of experiments. Satin widths from 1.0 to 5.0 mm were tested with multiple underlay density values, including repeated center-point runs to assess process stability. Once underlay was correctly configured, no catastrophic failures occurred, even on the tightest curves.

Observations and Interpretation

Several patterns emerged consistently across all tests. First, underlay configuration overwhelmingly determined whether freestanding satin lace succeeded or failed. Once Edge Run, Parallel, Zigzag, and Freestanding underlay were enabled together, structural failures largely disappeared.

Second, Underlay Density functioned as the primary structural tuning parameter. Adjusting underlay density allowed the same design to accommodate both very tight curves and wide satin stitches without redesigning the satin itself.

Third, Topstitch Width influenced visual character and forgiveness but did not independently determine structural integrity. Narrow satin stitches were more sensitive to curvature, while wider satin stitches tolerated looser underlay more readily. Topstitch Density, held constant throughout the study, was not required as a structural correction mechanism.

Minor defects did appear sporadically and migrated between curves across repeated runs. These variations are attributed to stitch phase alignment and local geometric interactions rather than unstable parameter choices. The absence of repeated, location-specific failures indicates that the system, once properly configured, degrades gracefully rather than catastrophically.

Practical Conclusions

Freestanding satin-stitched lace is fundamentally an underlay problem, not a topstitch problem. Freestanding underlay should be treated as a supplemental structural layer rather than a standalone solution. Traditional underlay types—Edge Run, Parallel, and Zigzag—remain essential even when stitching on wash-away stabilizer.

Underlay Density, not Topstitch Density, is the most effective lever for correcting structural issues such as stitch bundle separation on curves. Satin stitch width should be chosen primarily for aesthetic reasons, with underlay adjusted to support that choice rather than the reverse.

These findings validate the core design assumptions of StitchArtist while clarifying where published guidance oversimplifies real-world behavior.

Validation Boundary

The conclusions presented here are validated for freestanding satin-stitched lace produced with Madeira Polyneon 40 polyester thread (top and bobbin), two layers of water-soluble stabilizer, satin stitch widths from 1.0 to 5.0 mm, and curved geometry down to approximately 5 mm in diameter, using StitchArtist version 1.190. More extreme curvature or materially different threads and stabilizers may require additional tuning.

Closing Remarks

As an artist who spends a lot of time balancing precision with organic form, I found this project unexpectedly grounding. The experiments didn’t reveal a hidden trick so much as they confirmed a simple truth: structure matters, and when it’s done well, it disappears. With a reliable underlay, freestanding satin lace stops demanding attention and starts supporting intent. That’s when the process feels settled enough to let the designing take over again.

Acknowledgment

ChatGPT 5.2 from Open AI assisted in refining the experimental designs, interpreting the emerging patterns and documenting the findings.

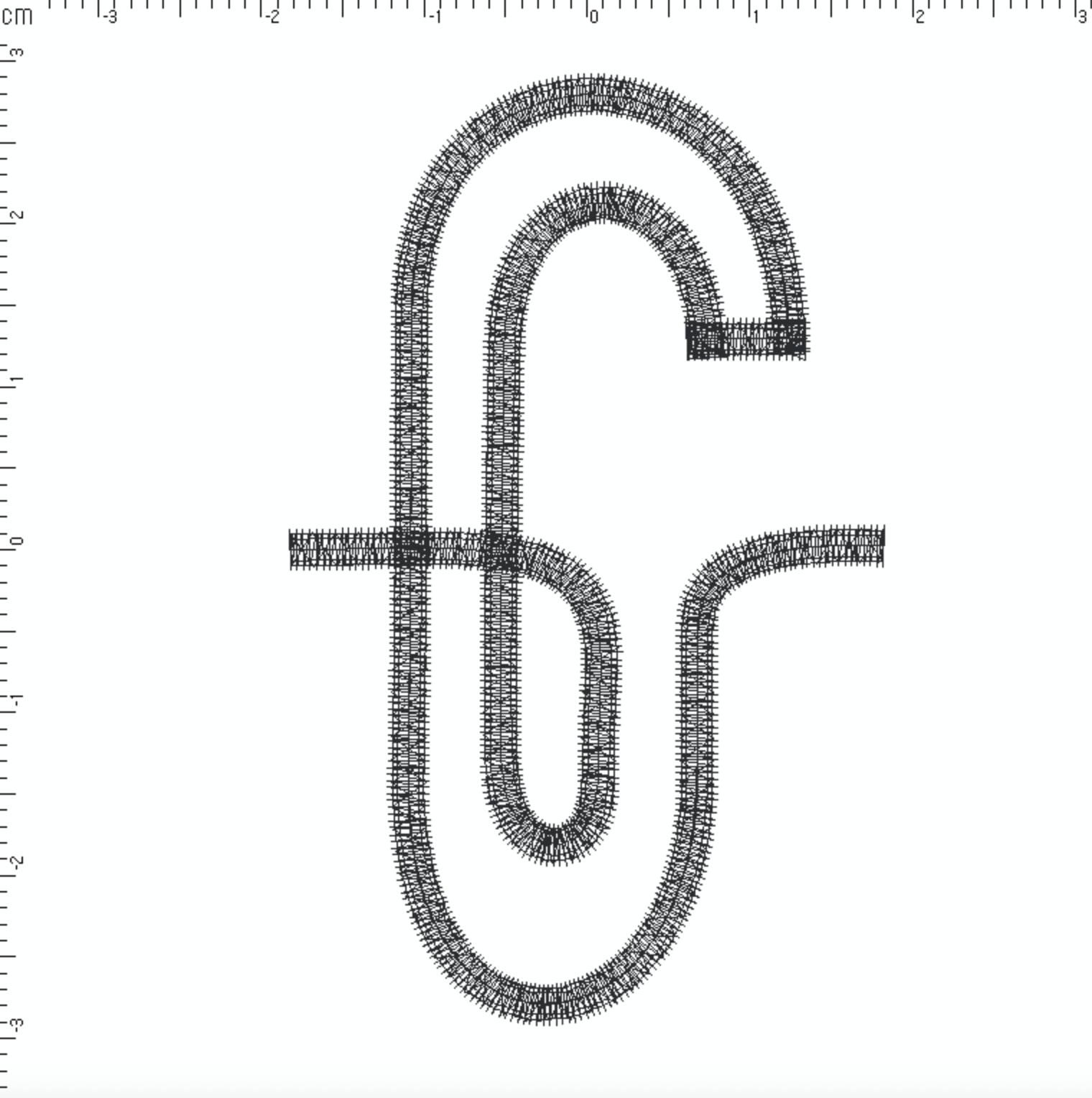

Appendix A - Test Sample Design in StitchArtist

Settings:

Satin Width: 2.5 mm

Topstitch Density: 4

Underlay: Edge Run + Parallel + Zigzag + Freestanding

Underlay Length: 2.5 mm

Underlay Inset: 2 pt

Underlay Density: 14 pt

Appendix B - Representative Samples

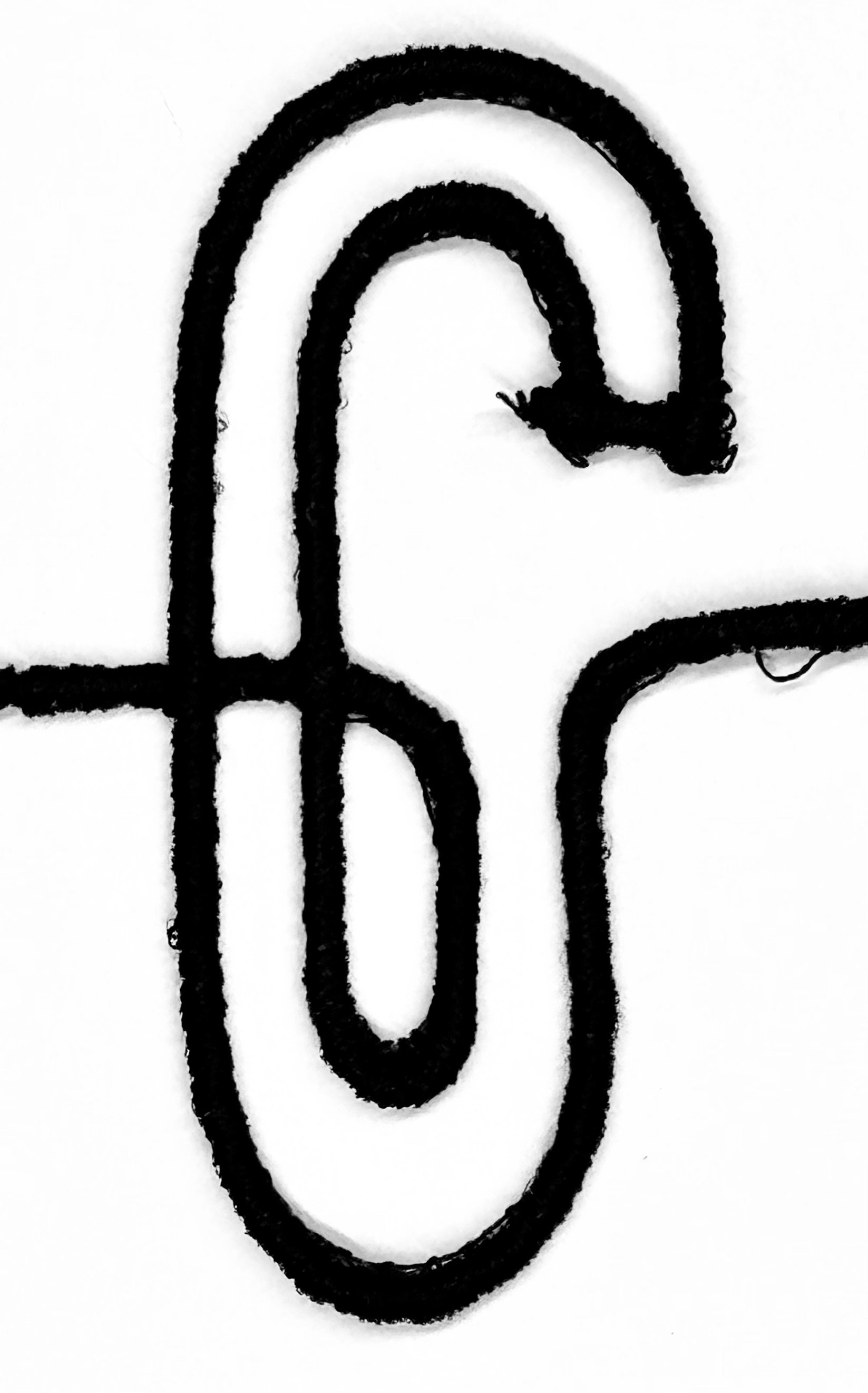

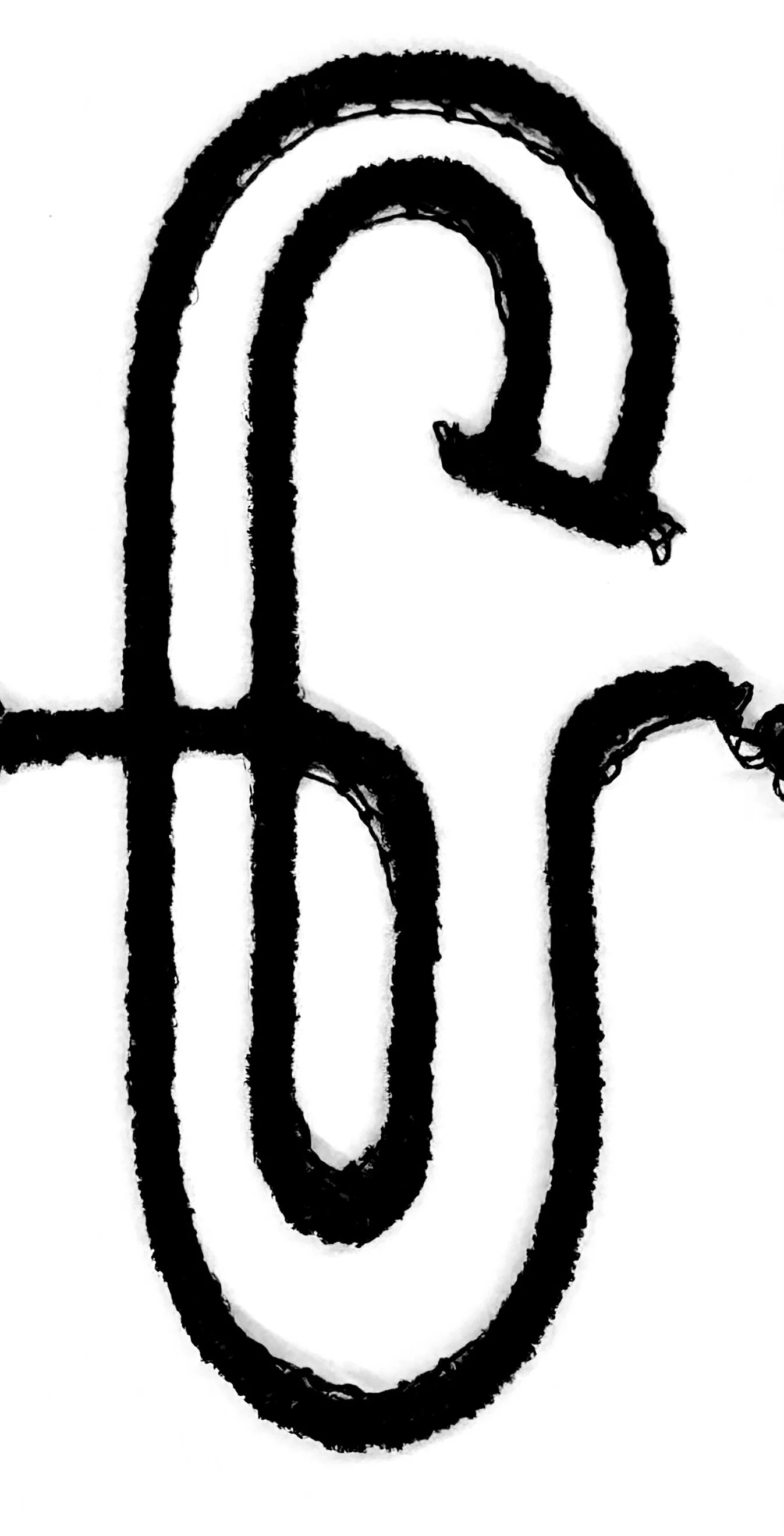

Three of the 75 samples stitched, finished and rated. From left to right:

Good result

Stitch bundle separation inside several curves

Final structure failure and lumpy Edge Quality